Our Precast Concrete Panel System

Leofric garages, sheds and workshops use one of two reinforced precast concrete panel systems, both designed for rapid on-site construction. Key features of both systems include;

- Virtually maintenance free

- Available in a choice of attractive finishes

- Simple foundations: designed for construction on a level concrete base

We believe our panel systems are the best in the industry, providing strength, security and easy erection. These same systems are in use in other buildings made by Leofric Building Systems, including small to medium-sized workshops, office and storage buildings, and larger industrial, commercial and community buildings.

1. Vertical Precast Concrete Panel System

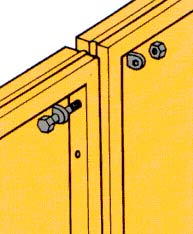

The walls of our vertical panel garages are constructed from 7ft (2.133m) high precast concrete panels, finished in natural stone aggregate and reinforced with steel. Panels interlock and are bolted together with rust resistant fixings. All external joints are sealed with mastic and finished with aggregate and all external bolt heads are concealed.

Our unique coupling system prevents any attempt to gain entry by slipping a blade between the panels and sawing through the bolts. We are the only manufacturer to incorporate this safety feature.

All panels are non-combustible and meet the statutory half-hour structural integrity and flame penetration requirements. Conformity standard information is available on request.

Choice of Finishes

We offer a choice of five aggregate finishes on all our vertical panel garages, at extra cost. (Alternatively, the customer may request plain panels, to apply their own coating.)

Unlike other manufacturers, we only use the highest grade aggregate for our garages, to ensure an attractive finish that lasts.

|

Canterbury: A multi-coloured, angular calcined flint, provides a tough finish merging well with landscape and many architectural styles. Unlike other manufacturers, we source our Sparlite from within the UK. | |

|

Brownstone: A dusky red crushed quartzite from Scotland, giving a wall finish blending well with red-brown brick environments. | |

|

Whitespar: Natural white Gabbrolit aggregate. Has a low porosity and is highly resistant to pollution. A practical choice where a reflective white finish is required. A small proportion of black granules adds interest to the texture and appearance of this finish. | |

|

Cotswold Stone: A golden honey coloured Cotswold stone from a pocket of Jurassic limestone, extracted just a few miles from our factory here in Gloucestershire. The environmentally conscious quarry has won awards for its efforts to encourage bio-diversity and minimize environmental impact. |

2. Precast Concrete Panel & Post System

As the name suggests, this method of construction uses concrete posts spaced at regular intervals, with the panels "stacked" between. Post and panels are shaped to accommodate each other. Panels are held firm with locking plates which attach to the posts.

Choice of Finishes

Panel & Post garages are available in two different finishes. They are usually supplied unpainted for the customer to apply their own coloring if desired.

|

Rockwall: A simulated brick finish to blend with your home. The concrete panels are moulded into this shape. Rockwall garages can be coloured to match the brick of surrounding buildings. | |

|

Logwall: Creates the natural look of a wooden, 'log cabin' type building with the durability and security of concrete. Can be stained to match any timber. This finish is only available on certain models. Call for details. |